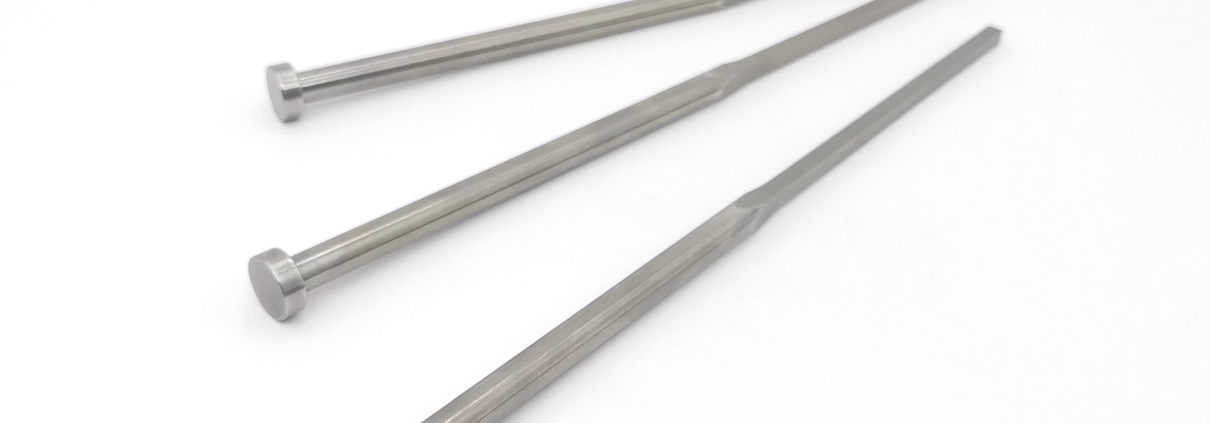

How to Make Mold Ejector Pins More Precise

How to Make Mold Ejector Pins More Precise

The precision of a mold ejector pin directly determines the overall quality of an injection mold. To make a mold ejector pin more precise, manufacturers must begin with high-quality materials such as SKD61 or SKH51. Proper heat treatment ensures the mold ejector pin maintains hardness while preventing deformation. Precision grinding and polishing are also essential to keep each mold ejector pin smooth and dimensionally accurate. During machining, using advanced CNC equipment can minimize tolerance errors and guarantee that every mold ejector pin fits perfectly with the mold cavity. In addition, consistent inspection with micrometers and projectors helps detect even the smallest deviations in a mold ejector pin. Regular maintenance, including lubrication and cleaning, extends the service life of the mold ejector pin and ensures stable performance. Ultimately, strict process control and attention to detail are key factors in producing a highly precise mold ejector pin that meets modern industrial standards.