The Importance of Locating Blocks in Mold Manufacturing

In the world of mold design and manufacturing, precision is critical. mold components during the injection molding process is essential for achieving high-quality, defect-free parts. One of the key components that ensure this alignment is the Locating Block. Despite its relatively simple appearance, the Locating Block plays a pivotal role in mold accuracy, efficiency, and overall quality control.

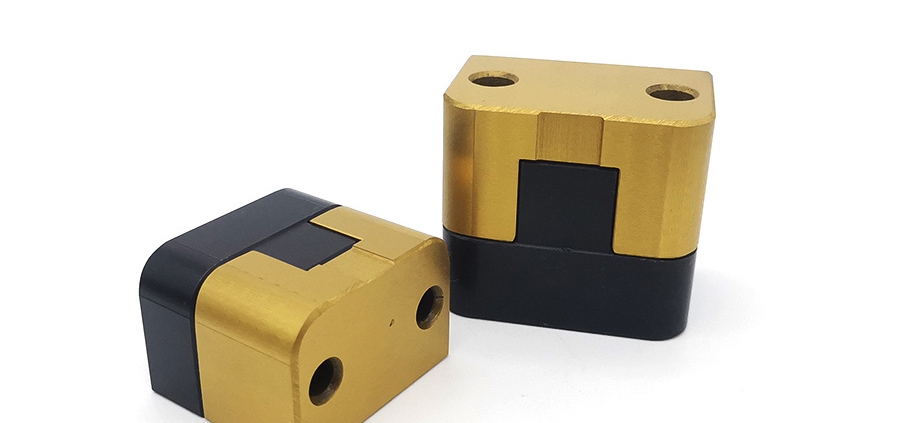

What is a Locating Block?

A Locating Block is a mechanical component used in mold tooling to provide a precise, stable location for aligning different parts of the mold, such as the core and cavity. It serves as a fixed reference point, ensuring that the two halves of the mold meet in the correct position when closing. maintain alignment throughout the molding cycle, preventing misalignment that could lead to part defects, excess wear, or even mold damage.

Precision and Alignment: The Role of Locating Blocks

The primary function of the Locating Block is to ensure the precise alignment of the mold’s core and cavity during the injection molding process. Without proper alignment, molded parts may experience defects such as flash, warping, or dimensional inaccuracies.

By ensuring that the mold halves come together in perfect alignment, the Locating Block helps maintain consistent part quality and repeatability in mass production environments. The use of Locating Blocks eliminates the possibility of uneven pressure distribution or misalignment between mold components, ensuring that the cavity forms with the correct shape every time.

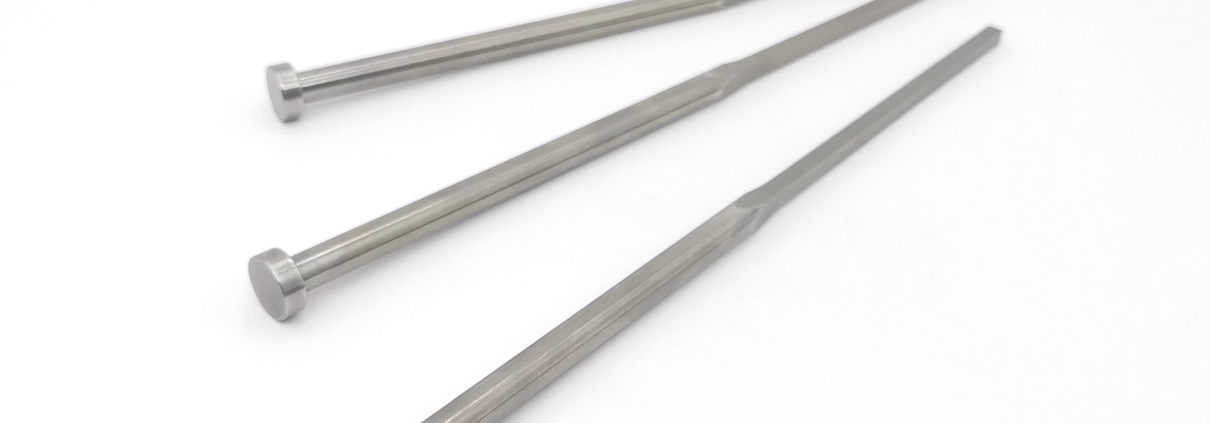

Durability and Wear Resistance

Another key advantage of using Locating Blocks is their ability to withstand the high pressures and temperatures involved in the injection molding process. Molds undergo thousands of cycles, subjecting them to mechanical stresses that can cause wear and fatigue over time.

Efficiency and Productivity

The role of the Locating Block extends beyond alignment to improve the overall efficiency and productivity of the molding process. By ensuring quick and accurate mold alignment, the Locating Block helps reduce cycle times. Mold setup times are minimized, and the need for manual adjustments or realignments is eliminated.

This efficiency is particularly important in high-volume production, where small improvements in alignment accuracy can result in significant gains in overall throughput. For example, in the automotive industry, where large numbers of identical parts must be produced quickly and accurately, the Locating Block is an integral component in maintaining the speed and efficiency of the production process.

Consistency and Quality Control

In mass production, consistency is paramount. Even slight variations in part dimensions can lead to quality control issues and potential product failures. Locating Blocks help ensure that every mold cycle produces parts that are within specified tolerances, contributing to better overall quality control.

With precise alignment achieved through Locating Blocks, manufacturers can expect consistent product quality throughout the production run, reducing the likelihood of defective or non-conforming parts. This consistency is especially important in industries where the parts must meet stringent regulatory standards, such as medical devices or aerospace components, where the cost of failure is high.

Cost-Effectiveness and Maintenance

While the Locating Block may be considered a small component in the overall mold, its impact on reducing maintenance costs is significant. Proper alignment ensures that the mold operates smoothly, reducing wear on other components and preventing costly mold repairs or replacements.

In addition, by improving part accuracy and reducing defects, Locating Blocks contribute to lower rejection rates, fewer rework cycles, and reduced scrap material.